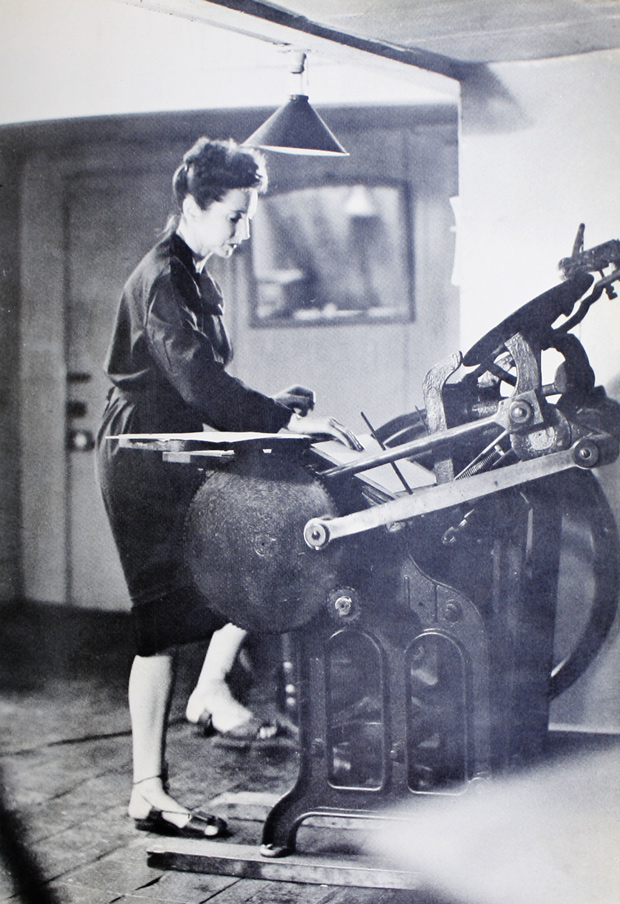

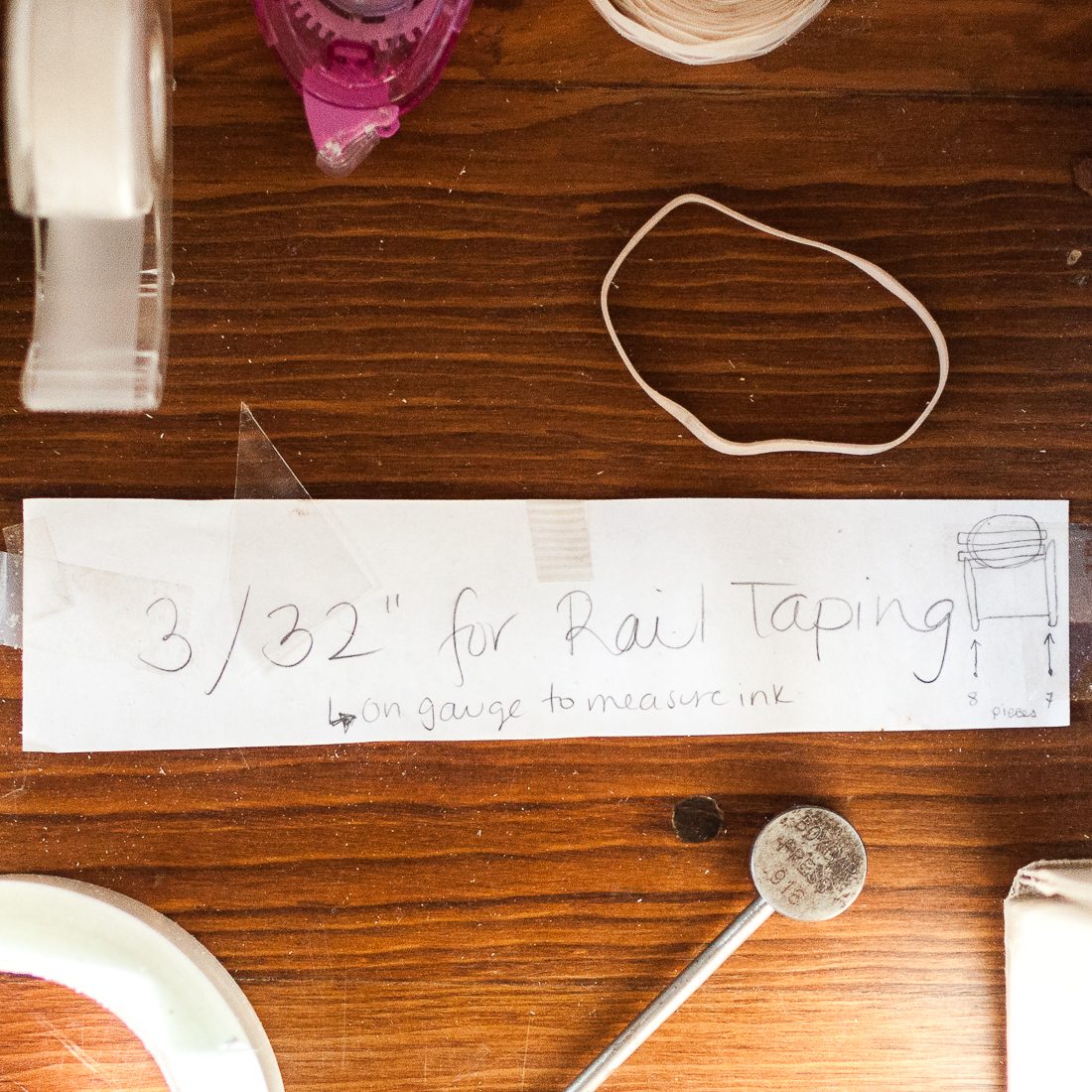

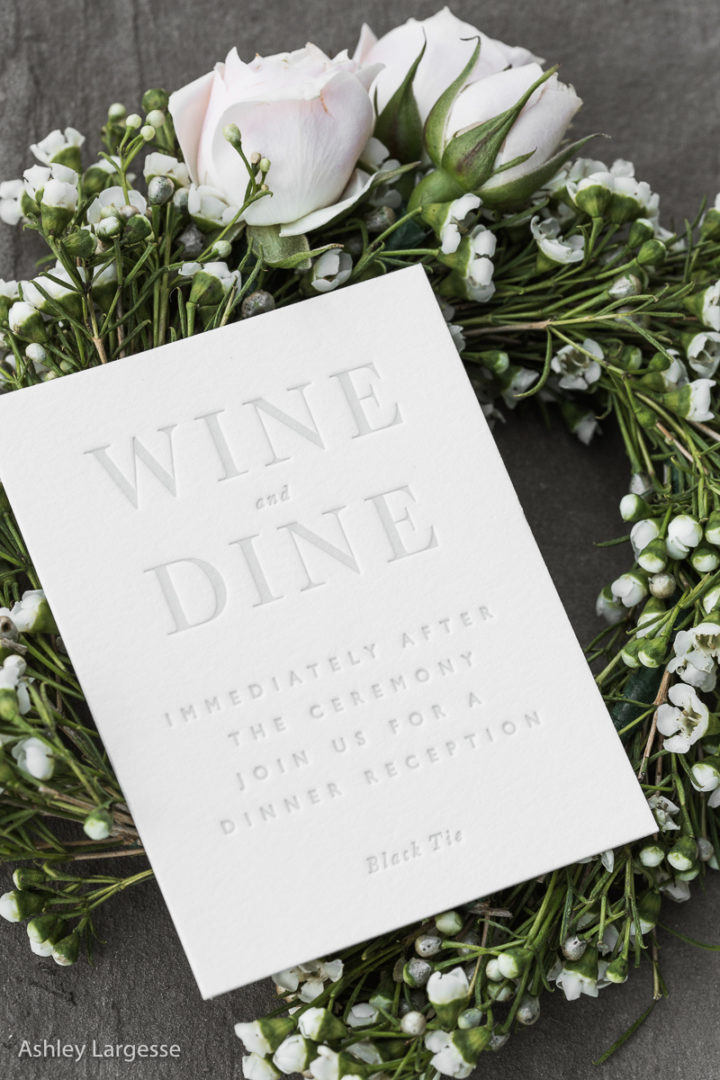

Preparing your design for print is a meticulous affair. Setting up the job takes as long as it takes to print the job. For example, for an invitation card that has two colors, the process is as follows. We measure and pencil in the placement of the design on card for the first color. Then we align the design on the letterpress, making sure that your text and borders are perfectly centered. We apply the ink by hand and by eye to get the color just right, and then reapply small dabs of ink every 50 prints to keep the color consistent. As mentioned, no electricity runs the press, it’s solely operated by foot. With a hefty spin of the flywheel to engage the press, the printer begins to print.

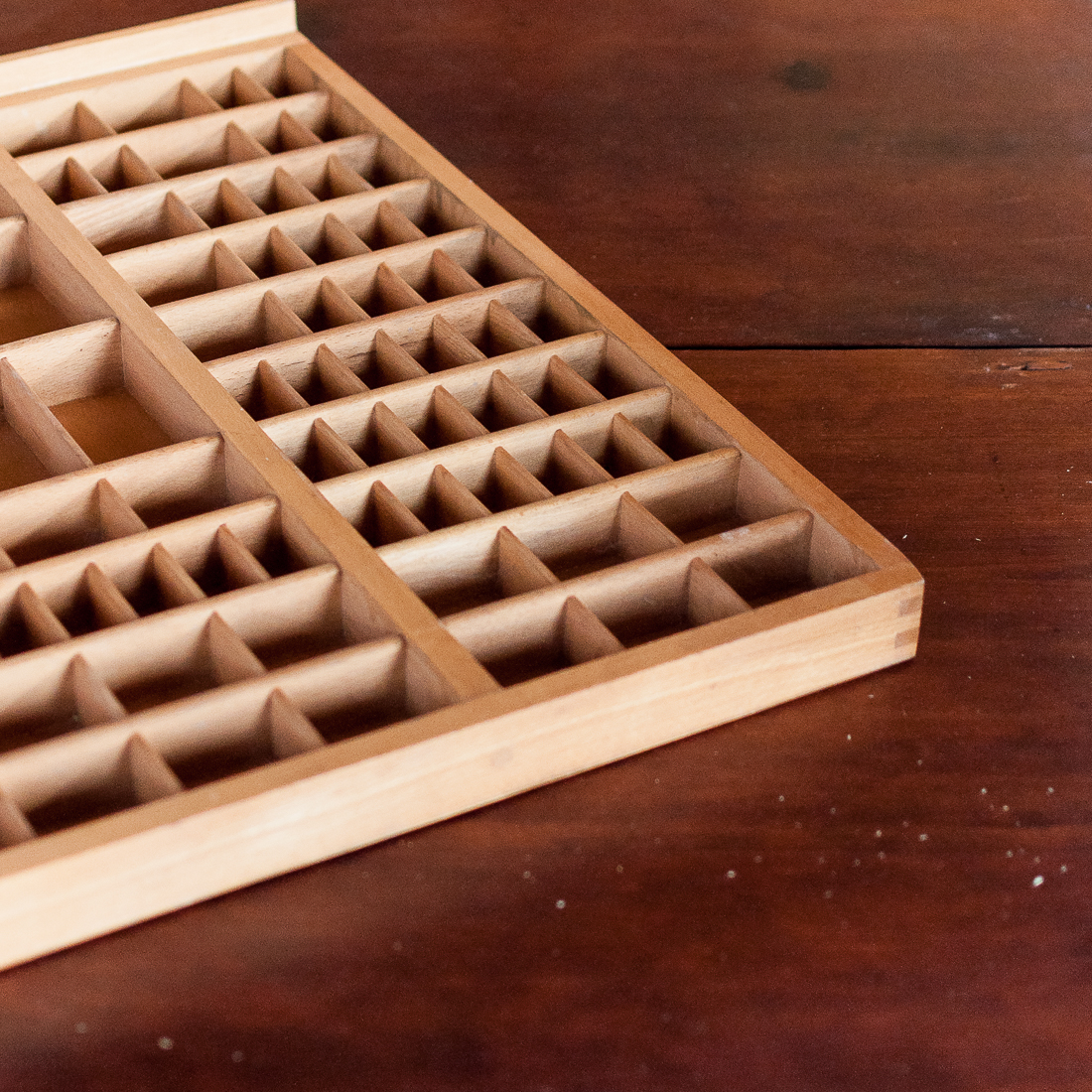

Every seventh pump produces a single colored print, one invitation. Each invitation card is hand-fed through the machine. Once finished, they remove design from the press and start the process over for the next card, such as the reply card, insert card, reception card, or envelope — until the first color has been printed on all the items. Then this process is repeated from the beginning for each additional ink color, making for a long, slow, yet rewarding process. The whole process can take days, but every minute of these hours ensures that we are thoroughly connected to the creation of something special. A pure commitment to our clients because curating heirloom treasures takes nothing less.